Synchrowood 8mm

Synchrowood 8mm

AC4 laminate flooring with 100% tropical hardwood HDF coreboard. European Standards EN13329 compliant.

From RM2.99/sq. ft.

Made in Germany

The overlay is a transparent film, impregnated with melamine and phenol resins for enhanced durability, that protects the decor paper underneath from mechanical influence. This top layer makes Synchrowood 8mm resistant to stains, wear, impact, burns and household chemicals.

Natural wood grain

You can feel the texture of fine wood grain on the surface of the floor. This texture is added based on digital scans of wood veneer.

Abrasion-resistant

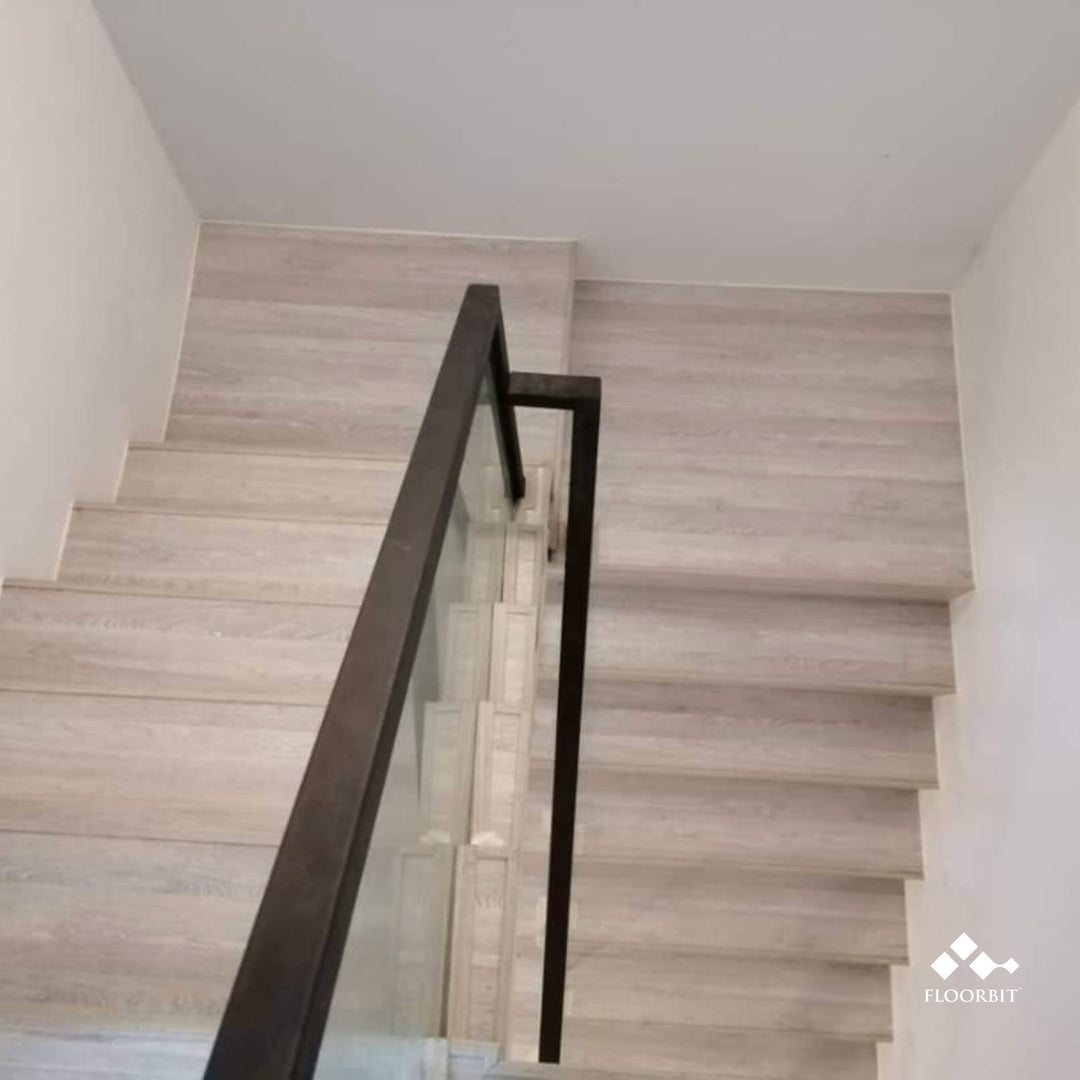

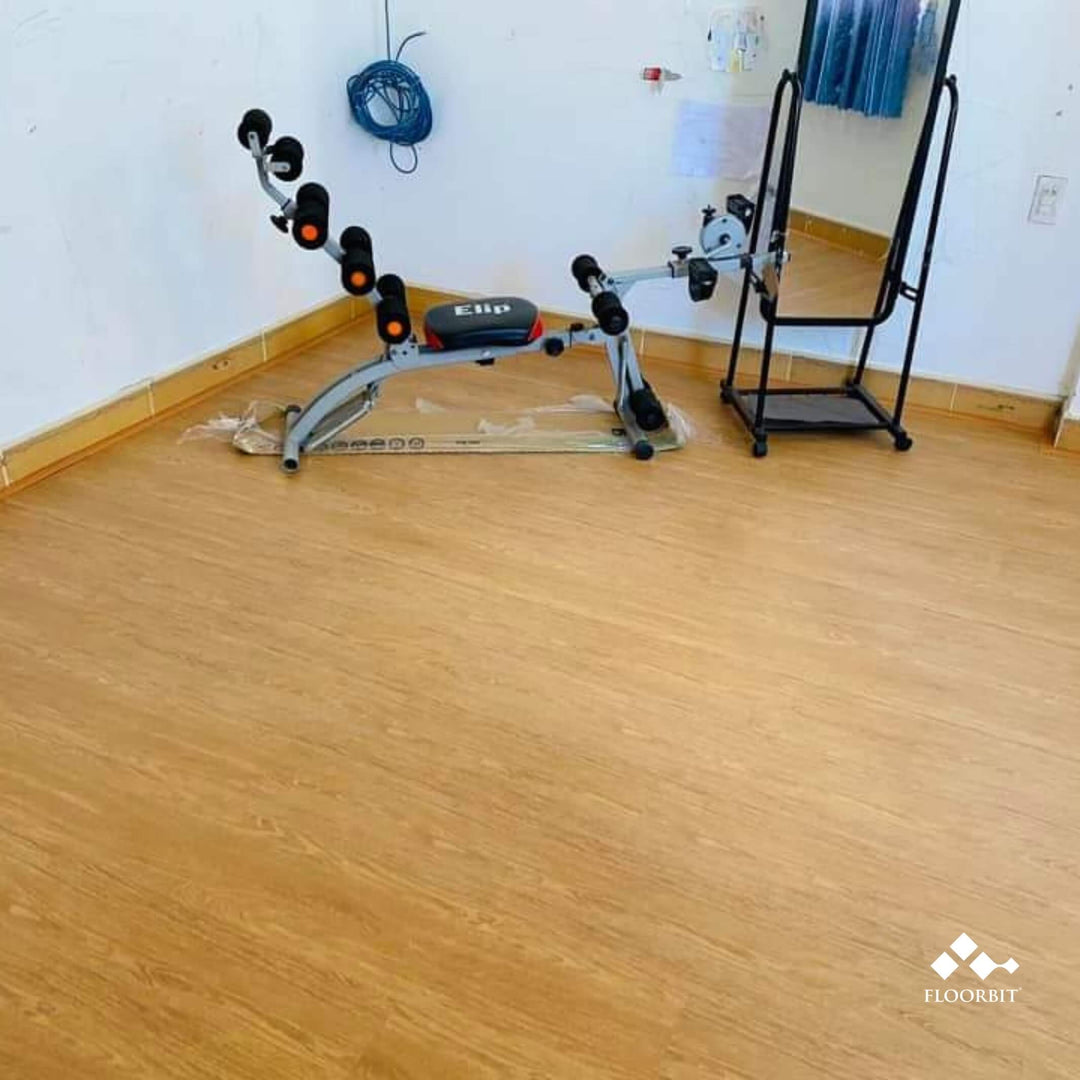

Rated as AC4, Synchrowood 8mm, is suitable for residential areas with heavy traffic, such as in kitchens and entrance halls, and commercial areas with medium traffic, such as in offices and boutiques.

Stain-resistant

Synchrowood 8mm is non-staining. Even furniture or chair castors leave no traces. The floor is easy to clean due to the tightly sealed surface, preventing dirt from sticking. Stains of all kinds, in the kitchen or otherwise, can easily be removed from the planks using acetone, thinner, or alcohol.

Anti-slip

The textures on the floorboards increase stability and reduce the chances of slips and falls. The anti-slip properties ensure a comfortable walking experience in all rooms.

Made in Italy

Decor describes the appearance of a floor’s surface. Wood surface reproduction is printed on the decorative paper using digital imaging techniques. Synchrowood 8mm has a high gloss surface.

Fade-resistant

The decorative paper is resistant to fading due to an aluminium oxide coating on the overlay. This prevents fading caused by exposure to a light to moderate amount of sunlight.

Made in Sarawak, Malaysia

The tropical hardwood high-density fibreboard (HDF) coreboard forms the basis of Synchrowood 8mm and provides stability to the product. This is where we find the largest proportion of wood, as HDF consists of highly compressed wood fibres. HDF provides better plank stability and allows the click profile to be precisely manufactured. Tropical hardwood HDF is twice as dense as softwood, so it is more resistant to wear and tear. The coreboard is also environmentally responsible because it contains wood by-products that would otherwise be burned or put into landfills.

The coreboards, sourced from Daiken Fibreboard Sdn Bhd, are made from selected tropical hardwood species such as Yellow Meranti and Red Meranti. Our coreboards do not contain plantation wood which is softer and lower density. Daiken factory has a proprietary wood chips control system that can control the mixing ratio of the different wood types, resulting in consistently high average HDF density. As a result, our HDF coreboards have an average density of above 900 kg/m³, significantly above the average density of regular HDF coreboards of 850-880 kg/m³.

Resistant to tropical climates

Our tropical HDF coreboards are tried and tested in many islands with hot and humid weather. For example, Taiwan, Singapore, Penang, Mauritius, and Bali. Tropical Hardwood HDF has higher moisture resistance compared to temperate hardwood HDF from countries like Thailand, India Europe and China.

Excellent moisture resistance

Thanks to its unique impregnation and board composition, the HDF core board has a high degree of hardness, density, and insignificant swelling behaviour to moisture. High moisture resistance prevents joints from swelling. In addition, all four sides of the Synchrowood 8mm planks are coated by a water-repellent agent made of paraffin and impregnating oil using a vacuum nozzle-powered injection system. Thus, the edges of the planks are well-protected from moisture.

Termite-resistant

Tropical hardwood has natural additives such as gum which are termite repellent. No insecticide is used during production.

Made in Germany

This waterproof melamine resin backing layer helps to balance the product and provides a high degree of dimensional stability. It ensures that the floor will not cup or bow when properly installed and maintained.

Engraved logo

Our logos are embossed at the back of each plank to signify the authenticity of the product.

The tropical hardwood HDF contains only recovered wood. These are wood waste collected from sawmills, forest management processes and roadside maintenance that would otherwise be burned or discarded. So instead of harvesting new trees, we only use wood by-products. We use no round logs and endangered trees in the manufacturing process of our products. Synchrowood 8mm does not contain any PVC, plasticisers (phthalates), heavy metals, pesticides or other harmful additives, thus reducing emissions. Rest assured that Synchrowood 8mm has an excellent environmental footprint, is safe to use and can be recycled at the end of its life cycle.

All our raw materials are Programme for the Endorsement of Forest Certification (PEFC) certified. PEFC is an international non-profit, non-governmental organisation dedicated to promoting Sustainable Forest Management (SFM) through independent third-party certification. The PEFC quality seal is based on very strict guidelines for managing forests in a sustainable manner and guarantees that timber is used from verified cultivation sources. The whole product manufacturing process, from raw material through to ready-to-use end product, is certified and verified by independent assessors.

The CE mark confirms that the product has been tested and meets all the EU-wide requirements for safety, health and environmental protection. Synchrowood 8mm also complies with EN 13329 to provide higher resistance against moisture, heat, abrasion, termite, fading, stains and impact, certified by Entwicklungs- und Prüflabor Holztechnologie GmbH (EPH).

The melamine resin is very safe because it is water-based and free from organic solvents. After curing, it creates a surface resistant to chemicals, water, organic solvents, light and temperature. Furthermore, the formaldehyde in the melamine resin is bound inseparably into the resin structure during curing and cannot escape into the ambient air.